SUSTAINABILITY AWARDS CUSTOM MADE

FROM ENVIRONMENTALLY FRIENDLY MATERIALS

Sustainability awards recognize organisations, leaders, and products driving positive environmental and social impact, covering areas like green innovation, circular economy, ESG (Environmental, Social and Governance), alongside net-zero strategies, with major ones including sector-specific accolades all celebrating best practices and measurable change for a greener future.

Diamond Engravers are one of the most technically advanced engraving service companies in the UK using the latest most advanced cool laser technology, sandblasting facilities, diamond drag engraving, MOPA fibre lasers, 3D laser engravers with 360 degree continuous rotary, complementary repair and restore facilities, brazing, tumbling, polishing, electroplating and hypo allergenic ceramic coating all in our factory. We are conscious of the need to minimise waste and use raw materials that are sustainable wherever we can.

We work with companies, schools and other establishments to design and manufacture meaningful awards that reflect achievements that help to look after our planet.

These awards include:

INNOVATION: New technologies, business models, and solutions for climate and environmental challenges. Impact: Measurable results in carbon reduction, waste management, circularity, and supply chain sustainability.

LEADERSHIP: Individuals and companies demonstrating commitment to long-term sustainable goals.

CAMPAIGNS: Effective purpose-driven marketing aligned with Sustainable Development Goals.

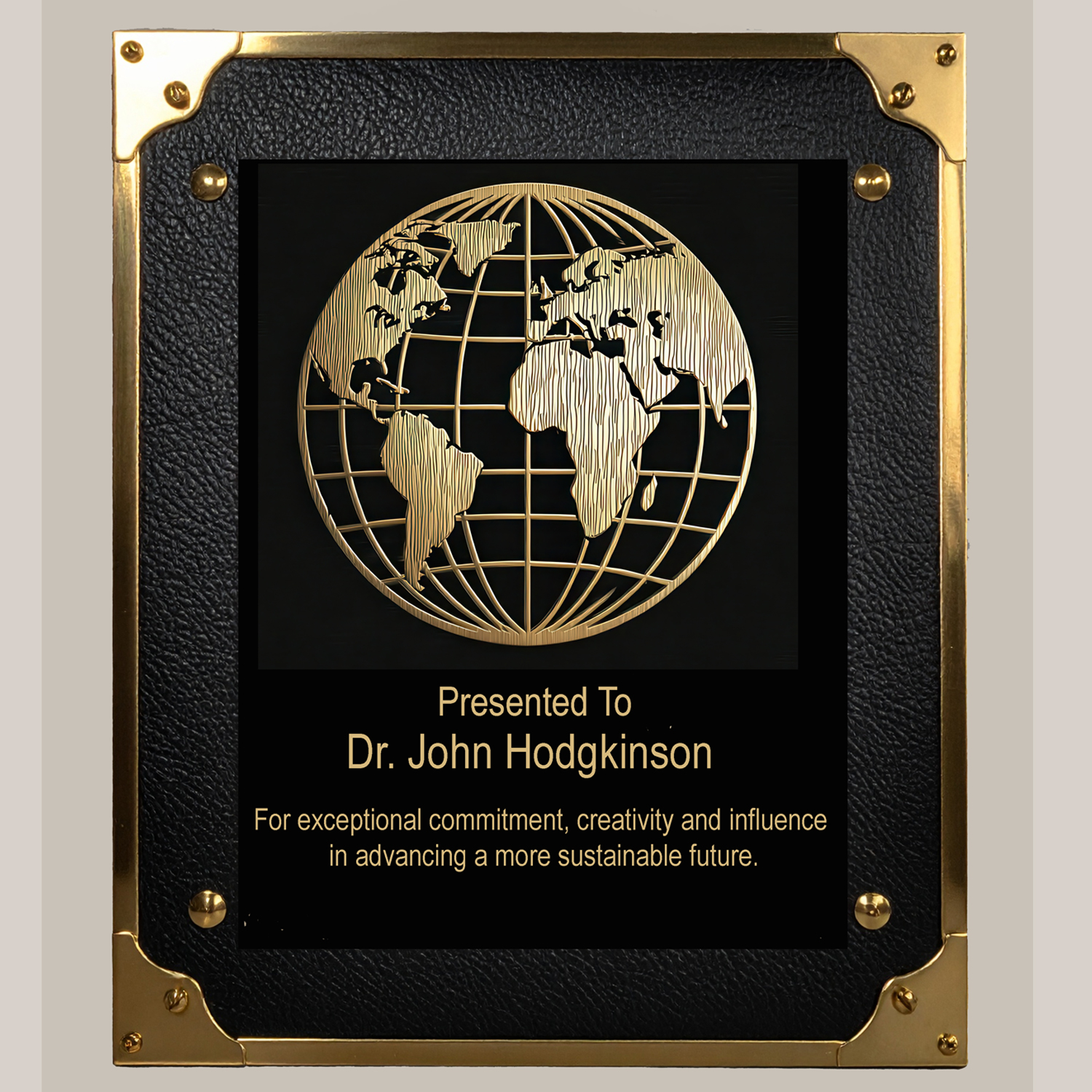

All our sustainability awards and trophies are designed and manufactured wherever possible in the UK. The products we make carry a certificate of authenticity and material list so that customers are aware of the composition of each product. Other products which are specifically imported are custom made to our design and supplied as components to be finished and engraved by us.

Diamond Engravers have invested in machinery and skillsets to develop the ability to design and manufacture bespoke sustainable awards and trophies. Key elements, the raw materials used in production are all environmentally friendly, can be recycled, production processes such as cool laser, no burn technology for the engraving of the organic products we make and the waste are all wherever possible recyclable.

Here are some of the materials we use and why.

Hi speed cutting machines waste, brazing using recycled silver, plating solutions, are all considered to minimise the environmental impact for these sustainability products. We are not just an engraving company, we are designers and manufacturers with over 20 plus years’ experience, our own degree qualified professional produces all our designs, 3d model- stl files, redrawn artwork and produces the visuals for all the college and university awards for approval before we undertake the work - ensuring no costly mistakes. Every project we undertake must be supported with a formal order and we provide in response an order confirmation and visual of the items to be engraved.

BRASS

Brass is 100% recyclable and infinitely reusable, meaning it can be melted down and reformed into new products endlessly without losing its strength or quality, making it a highly sustainable material that saves energy, conserves resources, and reduces waste in a circular economy. Infinite recyclability: It retains its key properties, like strength and conductivity, even after many recycling cycles, unlike some other materials that degrade. Energy savings: Recycling brass uses significantly less energy (up to 90% less) than producing new brass from raw materials, cutting down on greenhouse gas emissions. Scrap brass, including small bits from manufacturing or old fixtures, is valuable and easily put back into production, supporting sustainable practices

PLASTICS AND OTHER ORGANIC MATERIALS

Every component that is used to create the sustainability award is recyclable and can be used again in some form, certain of these products are infinitely recyclable and we will use our endeavour to use materials that minimise the impact to our environment. All our organic products used in the manufacture of these sustainable awards are carefully selected for each application.

WOOD

Process: Wood is sorted, cleaned, and shredded into chips, then processed for various uses. Products: Recycled wood becomes: Garden mulch or compost. Animal bedding. MDF (medium-density fiberboard) and chipboard. Paper and cardboard. Wood pellets for fuel (a carbon-neutral energy source). Benefits: Reduces landfill waste and greenhouse gases (methane from rotting wood).

STAINLESS STEEL

Infinite Recycling: Stainless steel is 100% recyclable and can be melted down and reformed into new products repeatedly, maintaining its strength and performance. Valuable Components: Its main elements (iron, chromium, nickel) are valuable and easily recovered, reducing the need for virgin materials. High Capture Rates: It has very high recycling rates, with significant amounts of old stainless steel being recaptured and reused. Environmental: Reduces landfill waste, conserves natural resources, and lowers energy consumption compared to producing new metal. Performance: Recycled stainless steel performs just as well as virgin steel, ensuring quality in new products

Working with our customers, we continually learn and develop products that are sustainable made in the UK and make a contribution to the safekeeping of our envronment.

|

|

|

|

| Eco Brass Coated Plaque |

Iroko Hardwood & Eco Brass |

Oak hardwood - 316 Stainless Plaque |

|

|

|

| Beech + Recyclable PMMA |

Wood Base PMMA/Crystal Plaque |

Various Hardwoods - Stainless or Brass |

|

|

|

| Custom Wood Brass Plaque |

Solid Brass Medallion |

Solid Wood Plaque |

|

|

|

| Wood Crystal Awards |

Custom Wood Brass Award |

Hardwood Medals Customised |

Sustainable branded awards made to order by Diamond Engravers

|